Description

3MM E-lock Vacuum Silicone Rubber Bag for EVA Glass Laminating Machine

Details Description:

Multi-use reusable vacuum bag systems manufactured from high performance silicone rubber compound. Laminated Glass is made by placing PVB or EVA interlayer films between two or more sheets of annealed/heat strengthened/tempered glass in the silicone vacuum bag. Each set of vacuum silicone rubber bag consists of one top and another bottom silicone sheets. The top and bottom silicone membrane sheet edges are sophisticatedly embedded to each other, to make sealed room for vacuuming. Interlocking of edges and corners are easy. Edges and corners are specially modified, such as locking strength grows larger when vacuum pressure becomes higher. Although it is tightly sealed, edges unlocking and opening are amusingly easy when vacuuming stops.

Product specification:

1) common thickness: 3mm

2) maximum width:3400mm with no joint

3) any length

4) common color: blue, white

5) lock type: E-lock sealing type

6) application: Pujol EVA glass laminated furnace, Keraglass, Microglass, TK Lamijet Convection,TEMA laminating kilns

Product Features

Heat-resistant, high elasticity, special surface property (no adhesion) and physiological inertia, oil resistant, solvent resistant, anti-aging, anti-corrosive, and non-polluting, EVA resistance.

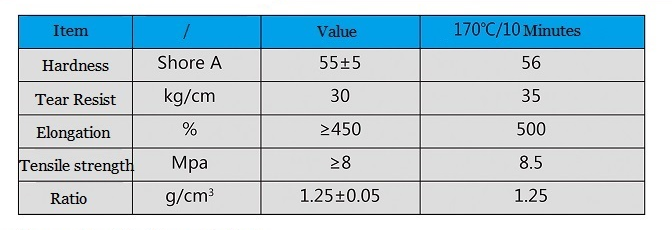

Tensile Strength

Top blanket of silicone rubber bag is more flexible. When vacuum pump is turned on, air in between top and bottom silicon sheets starts to evacuate. Top silicone rubber blanket begins to wrap downwards along glass edges until it gets in physically zero-gap contact with bottom silicone sheet. No air or gap is allowed in vacuum silicone bag. This specially formulated silicone rubber bag is highly elastic. It provides enough flexibility, allowing the silicone blanket to stretch until it fully wraps along glass edges. This remarkable property is especially important when glass is thick and/or curved.

Heat Resistance

Silicone vacuum rubber bag resists high temperature(more than 220C). Uniform Heating is applied on silicon blanket and glass all the time until interlayers, for example, EVA film is melted thoroughly. High temperature resistance is one of the important criteria of silicone vacuum bag.

Thermal Stability

Benefits include:

• Reusable silicone vacuum bag system saves time compared to traditional consumable lay up

• Decreased material waste

• Reduced risk of operator error

• Cost effective versus traditional consumables over the life of the bag

• Bespoke bags manufactured to customer’s exact requirements

• Maintenance and repair service available

• Currently being successfully used at 15 bar autoclave pressure

• Supplied with 6mm (0.25in) BSP vacuum fittings as standard (custom fittings also available)

• Designed for use with traditional breather fabric or PTFE mesh

• A range of compatible vacuum hoses and ancillaries available

Under heat and pressure PVB or EVA melts and gets bonded completely with the chemical properties of two or more sheets of glasses making it a single sheet of glass. On breaking the PVB or EVA interlayer films prevent glass from shattering or falling down. The inter layer films PVB or EVA provide excellent protection from uv rays and sound waves.

SACCO SILICONICO

SACCO IN GOMMA SILICONICA CON CHIUSURA A PRESSIONE

Sacco siliconico sp. 3 mm con chiusura a pressione dotato di speciale profilo maschio e femmina.

Perfetta tenuta del vuoto

Lunga durata

Ottima resistenza del profilo all'invecchiamento termico

REALIZZABILE IN QUALSIASI DIMENSIONE

Equipements pour fours

MANTEAUX SILICONE

CARACTERISTIQUES TECHNIQUES

◆ MANTEAUX SILICONE ◆

pour Fours de Laminage de Verre Feuilleté sous vide

Manteau ou Poche à vide pour Four de Laminage de Verre Feuilleté.

Chaque manteau est composé de 2 feuilles silicone. La feuille supérieure est raccordée au circuit de vide (Valve de raccordement à positionner puis à brancher au circuit de vide).

Ces manteaux sont conçus pour une utilisation dans les fours de laminage TEMA.

Nous conseillons l'utilisation de grille téflon à l'inetérieur du manteau (agit en tant que drain d'air et isole les verres du silicone).

Formats et dimensions :

- Largeur : 2 Largeurs standards disponibles : 2000 et 3000 mm

Silicone 2000 = 2000 mm de large

Silicone 3000 = 3000 mm de large

- Longueur : Au métre linéaire

After heating is completed, forced cooling is started. Silicone rubber bag is thermally stable for numerous rise and fall of temperature. Silicone rubber bag is tough. It allows glass loadings and unloading for numerously times. It resists abrasion, wear and tear up to a certain high degree. But to protect the silicone vacuum bag, it’s better you edging the glass before laminating. While the silicone bag is strong, the silicone bag is also flexible enough for easy handling when top blanket is opened and closed during glass loading and unloading.