Description

Silicone Diaphragm for Boostsolar Solar Module Laminator Lami-3

In the lamination process of solar panel production, the workers encapsulate all components with ethylene-vinyl acetate (EVA) adhesive film to ensure that module layers remain secure. That will cause high heat to melt the EVA films (typically 145-155°C). That’s why those solar module makers need our flexible, resilient, and durable silicone membrane sheets specially designed for use in solar laminators to provide compression on the photovoltaic panels in repeated cycle life.

The Lami-3 is our original & most popular silicone rubber sheet quality – combining hi-elongation, good life cycle performance under controlled environments and very competitive pricing. It is an irreplaceable element applied for the lamination process of solar PV panels and is available with both sides smooth or single-sided fabric impression surface finish.

Technical Data Sheet

Structure

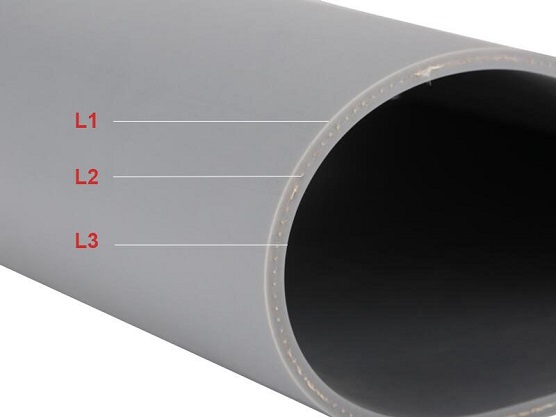

The Lami-3 gray silicone diaphragm is our well-proven standard product. Look at the right image to get a clear view of its structure.

Layer 1 - Grey Silicone Backing Material

Layer 2 - 1 Ply premium aramid fabric reinforcement

Layer 3 - Grey Silicone Backing Material

Durney’s grey solar membranes are well-known throughout the industry for their consistency and durability. With high tear and temperature resistance, these diaphragms are used worldwide on various solar module laminators.

Silicone Membranes For The Solar Industry

DURNEY– China leading manufacturer for silicone rubber membranes for solar PV module encapsulation in the renewable energy industry. We can choose from a variety of laminator brands and types. Depending on the solar module production line requirements, our silicone membranes are specially designed to fit many brands of solar panel laminators like Spire, Burkle, NPC, Meier, 2BG, Ecoprogetti, 3S, Komax, Electro Solar, Spaleck-Stevens, Nisshinbo, P-Energy, Mondragon, Boostsolar, Orient, ZST, Jinchen, SC laminators and etc.

Solar Membranes FAQs

Are you wondering if silicone rubber membrane is the right choice for your project? Our team is available to answer any questions you may have before submitting an official inquiry. We’ve compiled a list of the most common Frequently Asked Questions on the right to help you to make your own decision.

Can’t find the answer? Reach out to our customer support team.

1. Is your silicone diaphragm with or without a splice?

In our factory our super-wide calandars ensure that you can install silicone rubber sheets with no seam marks visible on the back sheet to produce solar photovoltaic modules. More customers are placing our silicone membranes for their solar module laminators.

2. Is the membrane’s surface finish smooth/smooth or smooth/textured?

We find the question of surface finishes interesting - but in conclusion, we see no evidence that one option is better than another. Common sense says that a fabric impression will provide a natural venting path to aid release, especially in hot/sticky conditions. Most of our customers do prefer fabric impression 1 side and smooth 1 side. The physical properties of the material will be exactly the same irrespective of colour or surface finish - these do not change.

3. What can we do to extend the life of our sheet?

During the laminating period, silicone membranes transfer the laminator's temperature and pressure to modules. To give extended life in a solar panel laminator, a layer of PTFE coated fiberglass faric sheet between the modules and the membrane is often suggested. Usually thickness can be 0.25mm or 0.35mm.

4. What's the best silicone rubber sheet for solar module laminator?

This is really a vital question and can be best discussed together face-to-face. There is no one answer that is right for everybody. There are many determining factors that can affect the choice of silicone diaphragm for example type of encapsulant, the composition of the modules, size of the modules, the brand of laminator, and budget constraints, etc.

5. How long should a silicone rubber membrane last?

Commonly our data shows that The 2nd Gen upto 4,000 laminating cycles and The 5th Gen upto 10,000 cycle life. As there are a number of variables beyond our direct control, it is very difficult to “guarantee” an exact cycle life.

6. What is your standard package?

For 1-5pcs, standard package is woven bags. When quantity is over 5pcs, they will be rolled inside a cardboard tube and then put onto pallets or into wooden cases. We will listen to our customers carefully.

7. Does color have any impact on membrane performance?

Based on feedback from customers worldwide, we can see no advantage or disadvantage of different colors. Actually, colors are now used to differentiate between suppliers.

8. What is EVA outgassing?

Outgassing refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Diaphragm/Membrane. This corrosion manifests itself in surface degradation (cracks) + excessive stretching & sagging.

9. Except silicone membrane, do you have other product name?

Although also called diaphragms, sheets, or membranes, the solar panel industry tends to use the term membrane.

At last, you might be also interested in the another types of solar silicone membranes from us.